-

-

About Us

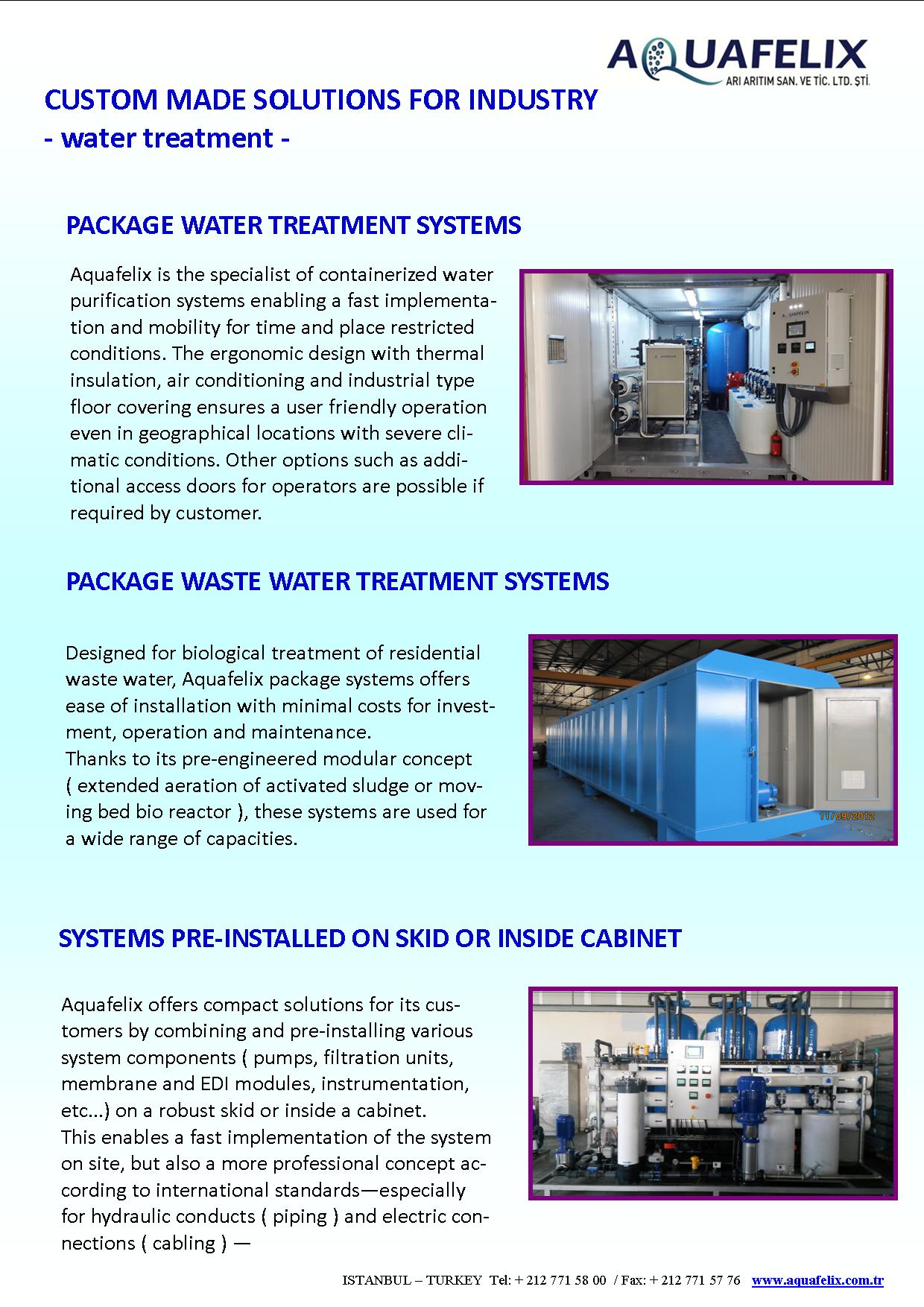

Aquafelix is a leading design and manufacturing company of water treatment systems. With an heritage of 20 years of experience and expertise, we deliver tailor made solutions to our customers for both industrial and commercial applications. This expertise acquired in water treatment process engineering on national and international scale since the nineties allowed us to expand our production range to other industrial process equipment such as;

* vertical or horizontal vessels, tanks, reactors, CIP units for various cleaning, chemical or physical processes

* pre-assembled piping spools, skids or manifolds

* MCC & PLC panels for automation and control

Our mission is to provide high quality, reliable equipment and services to the needs of users from all over the globe, by bringing together all our know how and energy.

-

Areas Of Operation

- Water And Wastewater Purification Apparatus And Equipments

- Pressure Vessels For Purification Sector

- Reverse Osmosis And Seawater Reverse Osmosis Systems

- Stainless Steel Chassis

- Stainless Food Collectors

- Ultraviolet Disinfection Systems

- Sand Filters

- Activate Carbon Filters

- Multi-Cartridge Filters

- Stainless Bag Filter

- Neoprene Coated Seawater Cartridge Filters

- Stainless Water Tank

- Pipe Lines Made of All Kinds of Materials(Stainless Carbon Steel Ctp Polyethylene Pvc)

- Plc / Mcc Panel Manufacture /Assembly

- Degassing Systems

- Water Softening Units

- Chemical Dosing Systems

-

Cartridge & Bag Filters

One of the easiest and economically affordable methods for particle removal from raw water is the filtration through a cartridge or a bag installed inside a close housing. By this way, a filtration rate at micron degree ( 10ˉ6 m. ) can be achieved, making product water without turbidity with a clear appearance.

AQUAFELIX uses various types of cartridges adapted to customer's needs, placed inside plastic or stainless steel filter bodies. Area of applications covers commercial to industrial usages.

On the other hand, AQUAFELIX Industrial type Cartridge Filters are the most reliable micro-filtration solution for various heavy duty applications. Their robust carbon steel construction with Neoprene lined interior enables treatment of high salinity water at high flow rates.

Features

• Up to 350 m3/h flow capacity ( as standard model )

• PVC, Stainless Steel or ST-37 Carbon steel housings

• 4 mm Neoprene coating inside ( Optional )

• Quick opening lid

• Air vents for start-up / drain

• Suitable for all type of standard cartridges

• Reliable and simple operation Flexibility in various applications; pre-treatment, polishing or sea water

• Conform to PED ( Pressure European Directive )

• Design pressure : 6 bar

• Max. working temperature : 60 ° C

back to products

-

Multi Media Filters

Media filtration is a widely used method to remove suspended solids and turbidity from raw water. Commonly known as a sand filter, a media filter contains multi layers of different minerals and compounds such as graded gravel at the bottom, quartz sand in the middle and anthracite on the top. Raw water flows in the downward direction through the media column and during its passage particles in suspension are removed by the media making filtered water free of turbidity with a clear appearance. For a specific pollution, such as high content of iron ( Fe ) and manganese ( Mg ), upper layer can be replaced by another media type, namely Aquamandix ( natural crushed manganese dioxide with catalytic action ) for Fe & Mg removal AQUAFELIX Vertical Media Filters are fully automatic units for removal of physical pollution (filtration efficiency : down to 20 micron). Filter's service and backwash sequences are automatically timer controlled by the use of pneumatic actuated butterfly valves via PLC control panel or by the use of top mounted control valves. Filter's tank are manufactured from Fiber Reinforced Plastic ( FRP ) for full corrosion resistance or from carbon steel coated with non solvent epoxy paint after sand blasting (metallic tanks manufactured according to DIN norms ).

Features

• Up to 130 m3/h flow capacity ( as standard model )

• Fiber Reinforced Plastic ( FRP ) , ST-37 Carbon steel or Stainless Steel tank

• Full automatic operation by the use of pneumatic actuated butterfly valves via PLC control panel or top mounted control valve

• 2 – 6 bar operational pressure

• Stainless Steel, Galvanized steel or UPVC & PP face piping ( according to models )

• Efficient water distribution and collection system inside filter tanks

• Air vents, sampling & drain valves, pressure gauges as standard instrumentation

• Backwash initiation by pressure differential ( optional )

• 4 mm Neoprene coating inside ( Optional )

• Factory tested

back to products

-

Activated Carbon Filters

Filtration through carbon layer is an effective method for removal of organic pollution, taste, color, odor and free chlorine in raw water. This media works via adsorption process, whereby pollutant molecules in raw water are trapped inside the pore structure of the carbon substrate. On the other side chlorine retention is essential to avoid damaging of reverse osmosis membranes by hydrolysis. As for the case of Media Filters, AQUAFELIX Carbon Filters are also fully automatic. Service and backwash sequences are automatically timer controlled by the use of pneumatic actuated butterfly valves via PLC control panel or by the use of top mounted control valves. Filter's tank are manufactured from Fiber Reinforced Plastic ( FRP ) for full corrosion resistance or from carbon steel coated with non solvent epoxy paint after sand blasting ( metallic tanks manufactured according to DIN norms ).

Features

• Up to 130 m3/h flow capacity ( as standard model )

• Fiber Reinforced Plastic ( FRP ) , ST-37 Carbon steel or Stainless Steel tank

• Full automatic operation by the use of pneumatic actuated butterfly valves via PLC control panel or top mounted control valve

• 2 – 6 bar operational pressure

• Stainless Steel, Galvanized steel or UPVC & PP face piping ( according to models )

• Efficient water distribution and collection system inside filter tanks

• Air vents, sampling & drain valves, pressure gauges as standard instrumentation

• 4 mm Neoprene coating inside ( Optional )

• Factory tested

back to products

-

Water Softener Systems

High level of hardness in water causes problems in water conducts such as lime scale or galvanic corrosion. This is also an unwanted situation for many industrial applications such as heating, dyeing, etc. process causing high demand of energy or consumption of high amounts of specific chemicals.

Water softening method depends on an ion-exchange resin - organic polymer containing cationic functional groups - in which "hardness ions" mainly Calcium ( Ca2+ ) and Magnesium ( Mg2+ ) are exchanged for sodium ( Na+ ) ions.

When all the available Na+ ions have been replaced with calcium or magnesium ions, the resin will be re-charged by eluting the Ca2+ and Mg2+ ions using a solution of sodium chloride ( brine solution ). The waste waters eluted from the ion exchange column containing the unwanted calcium and magnesium salts are typically discharged to the sewage system.

AQUAFELIX Softening Systems are fully automatic units. Softener's service and regeneration/backwash sequences are automatically controlled – based on the volume of raw water flowed through the resin column – by the use of pneumatic actuated butterfly valves via PLC control panel or by the use of top mounted control valves. Filter's tank are manufactured from Fiber Reinforced Plastic ( FRP ) for full corrosion resistance or from carbon steel coated with non solvent epoxy paint after sand blasting (metallic tanks manufactured according to DIN norms ).

Features

• Up to 220 m3/h flow capacity ( as standard model )

• Fiber Reinforced Plastic ( FRP ) , ST-37 Carbon steel or Stainless Steel tank

• Full automatic operation by the use of pneumatic actuated butterfly valves via PLC control panel or top mounted control valve

• 2 – 6 bar operational pressure

• Stainless Steel, Galvanized steel or UPVC & PP face piping ( according to models )

• Efficient water distribution and collection system inside Softener tanks

• Air vents, sampling & drain valves, pressure gauges as standard instrumentation

• Factory tested

back to products

-

Ultrafiltration ( UF ) Systems

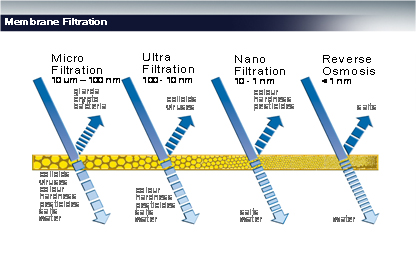

Ultrafiltration ( UF ) method is an excellent membrane technology enabling the most reliable solution to produce water that meets the highest standards for turbidity and microbiology.

This method can be used either for process water, potable water, sea water pre-treatment or waste water. Compared to conventional methods, UF system requires smaller installation area, offers full automation of the operation and produces very high quality water.

UF Removes

Silicates, Colloids, Particulate Matter, Algae, Bacteria, Coliform, Viruses, Giarda, Cryptosporidium, Oil and Grease and Proteins

UF Reduces

Total Organic Carbon ( TOC ), Color

more...

back to products -

Reverse Osmosis ( RO ) Systems

In a simple way, reverse osmosis systems can be described as an advanced filtration method with the use of semi permeable membranes for removal of dissolved ions and many types of molecules in water by applying external high pressure. The applied pressure is used to overcome osmotic pressure, a natural property driven by concentration of dissolved material in liquids and the result is that the solute is retained on the pressurized side of the membranes and the pure solvent is allowed to pass to the other side.

-Brackish water Reverse Osmosis ( BWRO ) Systems :

AQUAFELIX BWRO systems are manufactured to produce purified water from raw water sources with salinity ranging from 500 ppm to 15.000 ppm. Standard models feature all components mounted on skid controlled automatically by a PLC connected to a user friendly HMI consisting of a touch screen monitor ( for industrial models ). Operational pressure generally stays under 20 bar. In most cases, systems are preceded by a proper pre-treatment to avoid membrane fouling by sediments, hardness, organic matter, bacteria, silica, metal oxides or even chlorine.

Features

• Up to 125 m3/h product flow capacity ( as standard model on skid )

• TFC Spiral Wound Membranes

• Fiber Reinforced Plastic ( FRP ) or Stainless Steel Membrane Vessels

• PVC or Stainless Steel Cartridge Filter On System Skid

• Full automatic operation via industrial type PLC ( Siemens Logo for small capacities & Siemens S7 1200 for Industrial Models ) and Touch screen HMI panel

• Stainless Steel quality System Feed Pump

• CIP Unit For Automatic Flushing & Periodic Membrane Cleaning

• Stainless Steel High Pressure Piping ( Except commercial models up to 30 m3/day)

• Stainless Steel or Carbon Steel Skid paint with Epoxy

more...

back to products

-

Ultraviolet ( UV ) Sterilizers

Ultraviolet irradiation is an effective disinfection method using UV radiation ( short wavelength light compared to visible light ) to kill microorganisms such as pathogens, bacteria or viruses.

Electromagnetic radiation of AQUAFELIX UV sterilizers ranges at 254 nm which breaks molecular bonds within micro-organismal DNA, thereby prohibiting growth and reproduction of them.

Features

• Up to 150 m3/h flow capacity ( as standard model )

• Stainless steel corrosion resistant body and lamp reactor

• Long operational life time for UV lamp ( approx. 9.000 hours )

• 30.000 microwatt / cm2 dosing rate

• Panel mounted UV analyzer ( optional )

• Designed for simple installation & maintenance

back to products

-

Degasifier Systems

Degasifier units are used to remove dissolved gas such as hydrogen sulfide -H2S- or carbon dioxide -CO2- from water which flows in the downward direction in the degasifier unit, through the bed of Raschig rings. Air is introduced from the bottom of the degasifier by a radial fan and it passes through the raschig rings in the upward direction. The raschig ring bed ensures intimate contact between air and water. Gas content of water escapes from the top of the degasifier along with air and water is collected in the bottom tank by gravity.

AQUAFELIX degasifiers cover a wide range of flow capacity and commonly used for dissolved gas removal, especially to precede or follow RO systems.

Features

• Up to 200 m3/h flow capacity ( as standard model )

• Stainless steel or Fiber Reinforced Plastic ( FRP ) corrosion resistant, robust body for tower & bottom tank units

• Radial type fan with filter

• Bed of Raschig rings inside the tower

• Manual valve for discharge

back to products

-

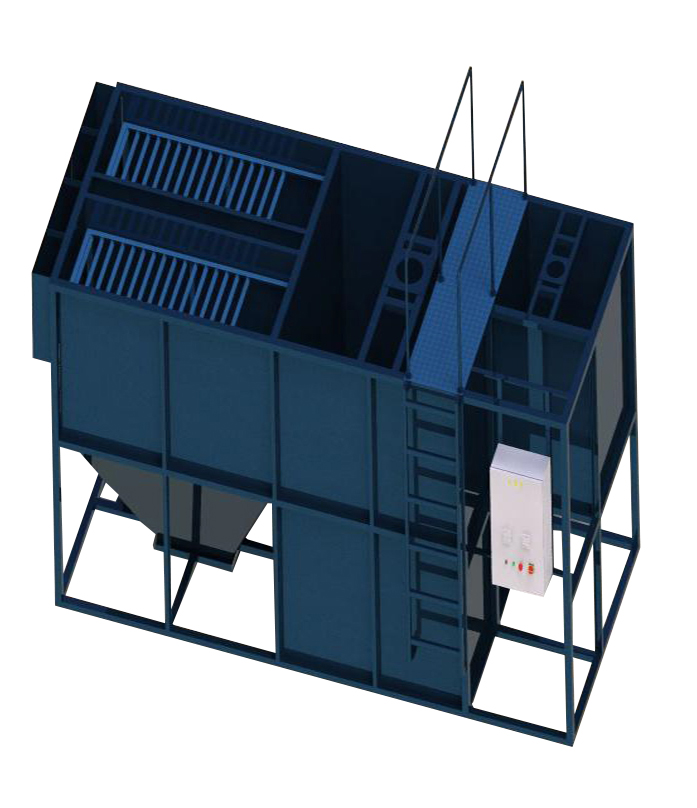

Clarifier Package Systems

AQUAFELIX Clarifier Package Systems are an effective solution for surface water treatment or for effluent of waste water treatment plants to remove solid particles by coagulation, flocculation and precipitation at final stage consisting of a lamella type clarifier section.

Our system process includes; -Automatic Chlorine Dosing Unit For Pre-chlorination :

In order to prevent bacteriological activity by oxidation, Chlorine dosing is be applied at pumps group inlet. For this purpose, Electronic Metering Pump with reliable performance and resistance to a wide range of chemicals will be used.

-Feed Pumps group :

Intake of raw water to clarifier system will be ensured by feed pumps group. Critical parts of pumps will be manufactured by stainless steel quality material. A -Y- type strainer will remove debris at the inlet of pumps.

more...

back to products

-

Ultrafiltration ( UF ) Systems

Advantages Of UF Usage For RO System Pre-treatment

-As UF method produces high quality pre-treated water, SS, SDI, etc..values are very low in RO feed water, so decreasing membrane's chemical cleaning frequency and minimizing cleaning and maintenance costs.

-RO system membranes life time is increased.

-Addition of specific chemicals for pre-treatment such as coagulants or polyelectrolyte is decreased.

-Risk of SS leakage to RO feed is eliminated.

Features

For Surface Water or Sea water

• Up to 215 m3/h flow capacity ( as standard model on skid )

• Vertical Type Hollow Fiber Modules

• Full automatic operation via industrial type PLC ( Siemens S7 1200 ) and Touch screen HMI panel

• 316 Stainless Steel quality System Feed & Backwash / CEB pump

• PE or PVC Piping

• High Quality, Chemical Resistant Dosing Units

• Carbon Steel Skid paint with Epoxy

For Spring Water

• Up to 120 m3/h flow capacity ( as standard model on skid )

• Horizontal Type Hollow Fiber Membranes

• 316 Stainless Steel quality Membrane Vessels

• Full automatic operation via industrial type PLC ( Siemens S7 1200 ) and Touch screen HMI panel

• 316 Stainless Steel quality System Feed & Backwash / CEB pump

• 316 Stainless Steel quality Piping ( Industrial or Food Grade )

• High Quality, Chemical Resistant Dosing Units

• 304 Stainless Steel quality Skid

back...

back to products -

Reverse Osmosis ( RO ) Systems

-Sea Water Reverse Osmosis ( SWRO ) Systems :

For geographical areas that have either no or limited surface water or groundwater, SWRO systems are an increasingly common method of desalination, because of their relatively low energy consumption. In recent years energy consumption has dropped to around 3 kWh / m3, with the development of more efficient energy recovery devices and improved membrane materials. According to the studies of International Desalination Association in recent years, SWRO method was used in 66% of installed desalination capacity in the world.

Similar to BWRO systems, AQUAFELIX SWRO units are also skid mounted type for standard models and treat raw sea water with salinity ranging from 15.000 ppm to 45.000 ppm. Pressurizing unit of the systems consist of a high pressure pump coupled to a booster pump and a pressure exchanger for energy recovery. Operational pressure generally stays under 70 bar. In most cases, a proper pre-treatment to avoid membrane fouling is placed before the systems.

Features

• Up to 50 m3/h product flow capacity ( as standard model on skid )

• TFC Spiral Wound Membranes

• Fiber Reinforced Plastic ( FRP ) Membrane Vessels

• PVC or Neoprene Coated Carbon Steel Cartridge Filter On System Skid

• Full automatic operation via industrial type PLC ( Siemens S7 1200 ) and Touch screen HMI panel

• Stainless Steel quality System Feed Pump

• CIP Unit For Automatic Flushing & Periodic Membrane Cleaning

• Stainless Steel High Pressure Piping

• Stainless Steel or Carbon Steel Skid paint with Epoxy

back...

back to products

-

Clarifier Package Systems

-Automatic Chemical Dosing Units :

For coagulation & Flocculation purposes, Alum - an inorganic salt - and Polyelectrolyte will be dosed as pre-treatment to bind any small particles before the lamella section of the clarifier. For this purpose, Electronic Metering Pump with reliable performance and resistance to a wide range of chemicals will be used.

-Coagulation & Flocculation Chambers :

First 2 sections of the clarifier will consist of Coagulation & Flocculation chambers where rapid and slow mixing processes occur.

-Lamella Clarifier Section :

Lamella Clarifier section features racks of inclined, ondulated GRP plates, which cause flocculated material to precipitate from water that flows across the plate.

Conventional clarification equipment requires a much larger surface footprint in order to match the solids removal capacity of a lamella clarifier. The compact design essentially eliminates any hydraulic disturbances caused by wind or temperature changes that may be problematic with conventional clarifiers located outdoors

Features

• Up to 200 m3/h flow capacity ( as standard model )

• Vertical type fast mixer in coagulation section ( manufactured from epoxy coated carbon steel )

• Vertical, paddle type slow mixer in flocculation section ( manufactured from epoxy coated carbon steel )

• Lamella clarifier section with racks of inclined, GRP plates for compact design ( manufactured from epoxy coated carbon steel )

• Electronic Metering Pumps with resistance to a wide range of chemicals

• Sludge return pump ( optional )

• Separate IP 54 Class Control panel

back...

back to products

-

Industrial Steel & Plastic Structures

• Pressure Vessels, Storage Tanks

• Process Equipment

• Mixers, Reactors, CIP Units

• Piping Spools

• Modular / Pre-assembled Skids

• Electric Instrumentation & Automation

back to products

-

Contact us

Contact Form

ARI PURIFICATION IND. AND TRADE COMPANY LTD.

Ömerli Mahallesi

Hakkı İleri Cad. No:76/A

ARNAVUTKÖY /İstanbul / Türkiye

Tel:+90212 771 5800

Fax:+90212 771 5776

E-mail:sales@aquafelix.com.tr E-mail:info@ariaritimltd.com Web: www.aquafelix.com.tr -

Degassing Systems

Applied for the purpose of eliminating hydrogen sulfide (H2S) and carbon dioxide (CO2) gases from water sources. Hydrogen, which changes places with cations in water that passes through cation-changing resin, causes acid formation. Carbondioxide occurs as a result of acid’s contact with bicarbonate ions. In addition, carbondioxide will also occur in conditions such as dosing of acid in reverse osmosis feed water. Carbondioxide can pass through reverse osmosis membrane element. Carbondioxide degasser is used in such cases.

Water enters into unit from the distribution diffuser placed at the top of the degasser. It flows downward by getting in touch with polypropylene rings which are filled into the top tower of the degasser. In the meantime, the air that is blown by the degasser fan gets in touch with water and flies by incorporating carbondioxide in water. Purified water is accumulated in a tank at the lower base of the degasser.

-

Active Carbon Filters

Active Carbon filters are used with the purpose of improving taste, odor and color, chlorine and chlorine compounds, and filtering THMs and all the organic materials in water. Filter columns contain quartz as the lower bed material and active carbon as the main bed material. Due to large active carbon surface areas, it takes pollutions adsorption, in other words keeping on the surface method.

Active carbon minerals purify water by absorbing the chemical and organic matters. For this reason, active carbon filters are systems that conduct physico-chemical purification.

Fully-automatic valves are used as the control unit. System automatically performs the backwash process and passes in the accumulated pollution to the drainage line according to the time set through the valve without the need for human intervention. The system automatically returns back to the service mode after the cleaning process.

The surface piped systems consisting of pneumatic or electric actuator valves are used in the industrial type active carbon filters. The system can get into backwashing period with differential controlled pressure according to time, debit or pressure transmitters placed at the filter entry and exit. It can automatically return back to the service mode after the completion of the cleaning process. PLC is used as controller and 65,000 color TFT touch screen is used as operator panel in the system.

-

Reverse Osmosis Systems

In its most general definition, reverse osmosis system is a process of removing anion and cation ions found in water. Reverse osmosis system, also used as a kind of advanced filtration method at the same time, are high-level water purification elements which employ the latest facilities of high technology. The operation principle of these systems can be explained with the reverse operation of the osmotic balance in nature. It requires more pressure than osmotic pressure in order to reverse the osmotic balance. For this reason, high-pressure pumps are used in reverse osmosis systems. Water, pressured by high-pressure pump, is passed over to the membranes with 5 angstrom sized pores on and thus the purification of water takes place. The heavily-concentrated water coming out of waste line is forwarded to the drainage.

Reverse osmosis systems, whose fields of use are increasingly expanding, are safely used in every industrial areas and domestic applications. Due to the degradation, pollution and disappearance of natural water springs especially in recent years, many famous companies in bottled water business performed the purification of drinking water with reverse osmosis systems and distributed in the market.

In addition, reverse osmosis systems, used within availability of fresh water from seawater, also provide excellent results in recycling wastewater or a variety of liquids mixed with water by means of special type of membranes.